🚧 “Digital Dust in the Air”🚧

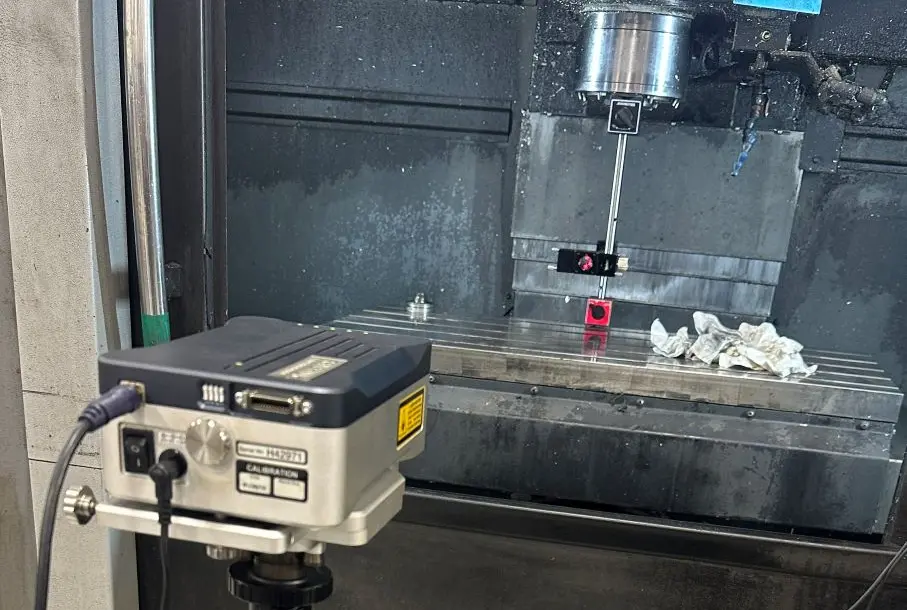

Renishaw XR20 Rotary Axis Calibrator

Our service now includes full rotary axis calibration using the Renishaw XR20-W system. This advanced tool delivers high-accuracy measurement of rotary positioning performance, ensuring your 4th and 5th axes meet the most demanding tolerances. With a resolution down to ±1 arc second, the XR20-W allows us to verify and optimize rotary axis performance for improved machining accuracy and reduced scrap. Whether you need compliance with ISO standards or peak productivity, we’ve got the capability to keep your machines performing at their best.

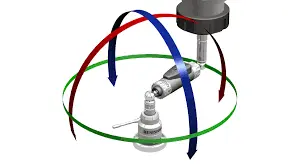

Renishaw Ball Bar

Ball bar testing is a highly effective diagnostic tool that evaluates your CNC machine’s ability to perform precise circular movements. By identifying issues such as backlash, servo mismatch, and axis misalignment early on, we can ensure your equipment continues to operate within tight tolerances—reducing scrap, minimizing downtime, and improving overall productivity.

Advanced CNC machining

Proper pitch error compensation on a CNC machine is essential for achieving high precision and consistent part quality. It corrects inaccuracies in the machine’s ball screws by adjusting command pulses to match actual movement, ensuring accurate tool positioning. This reduces dimensional errors, minimizes scrap and rework, and allows the machine to operate at its optimal performance.

Partners and collaborations

We proudly partner with leading industry innovators to advance CNC technology and deliver exceptional service to our clients. Through strategic collaborations, we continuously improve our capabilities and stay at the forefront of precision machining.